One/Two Loop Bags are widely used as they are easy to lift with their single or double lifting loop. These Bags reduce storage space and are highly cost-effective making them ideal for transportation and storage of materials in bulk.

Application:

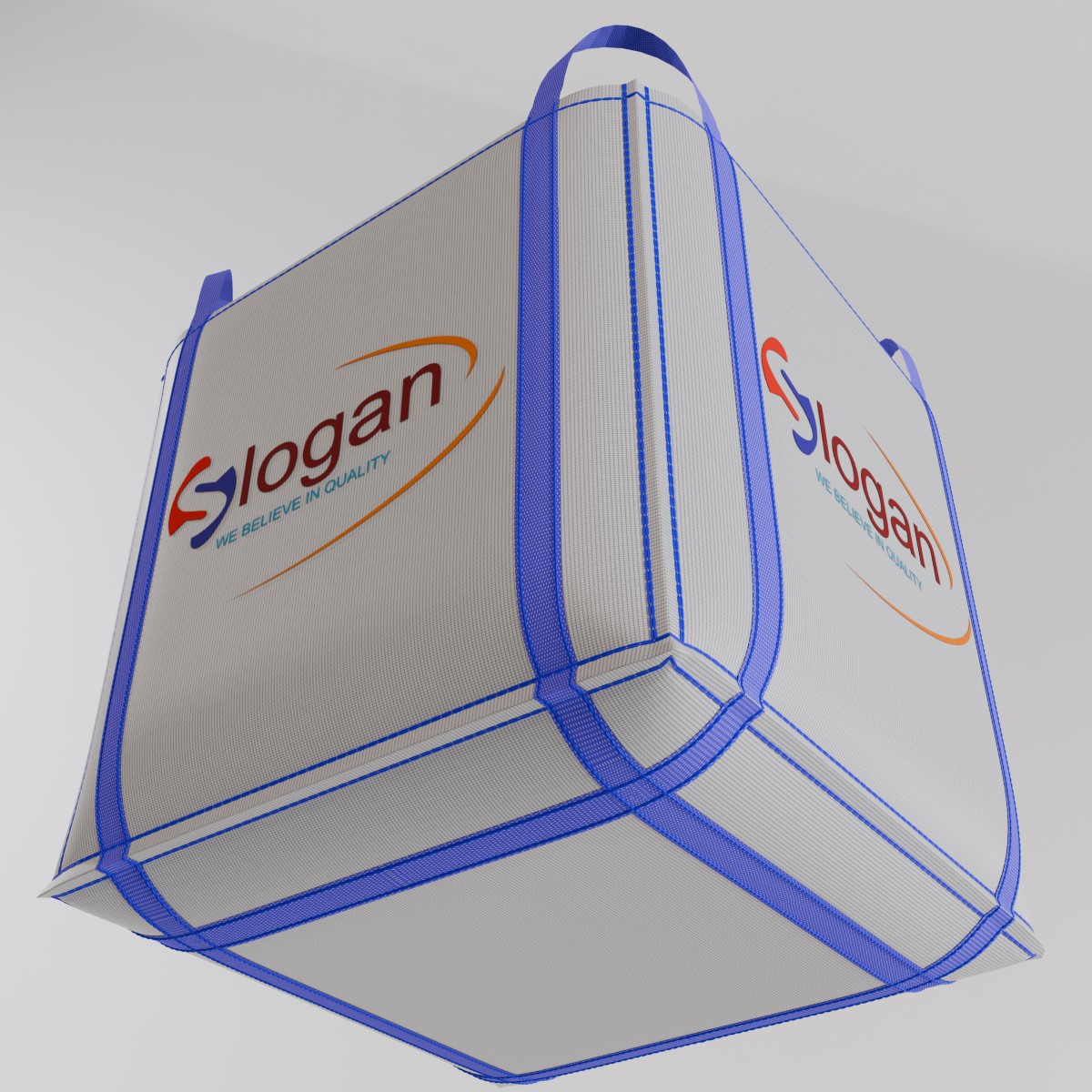

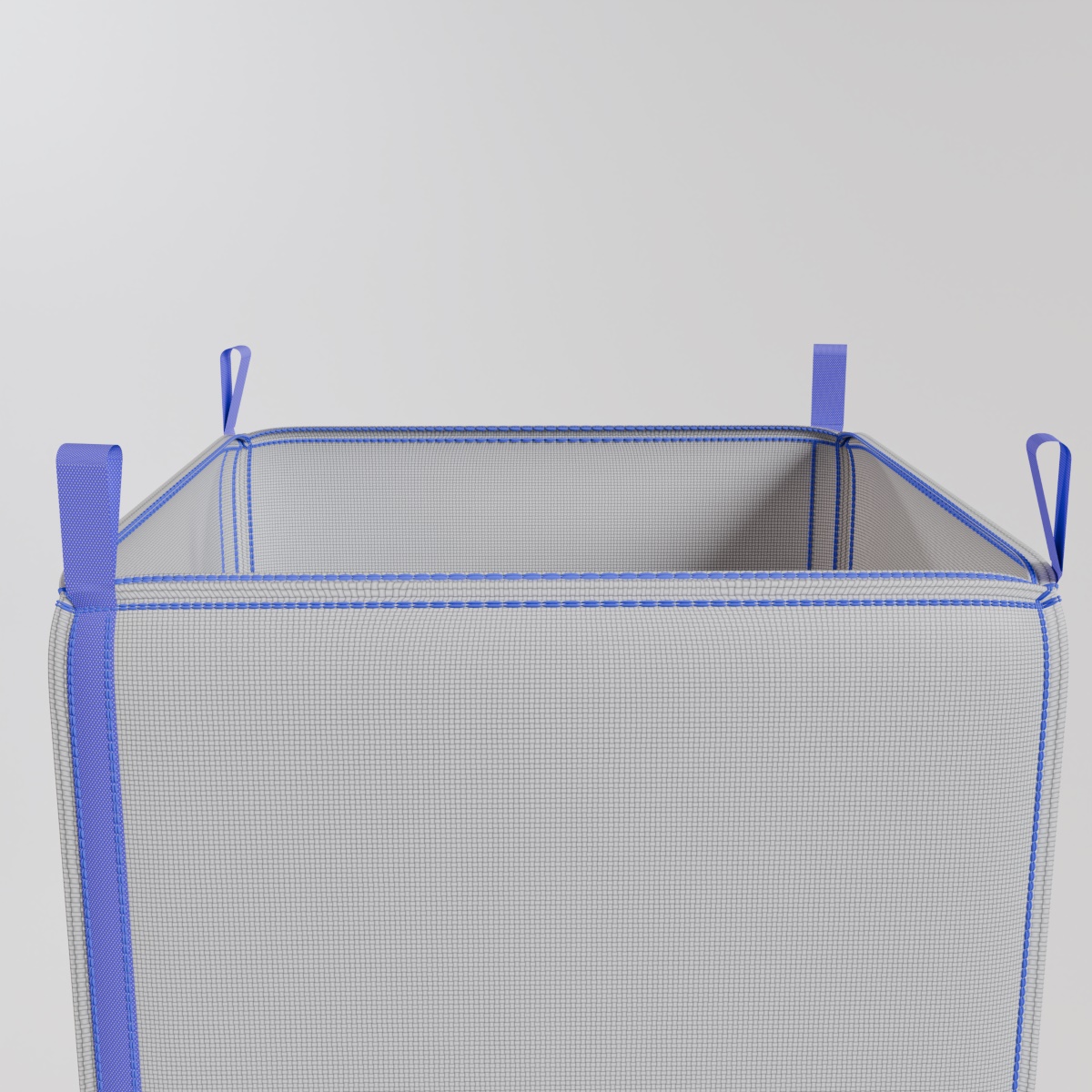

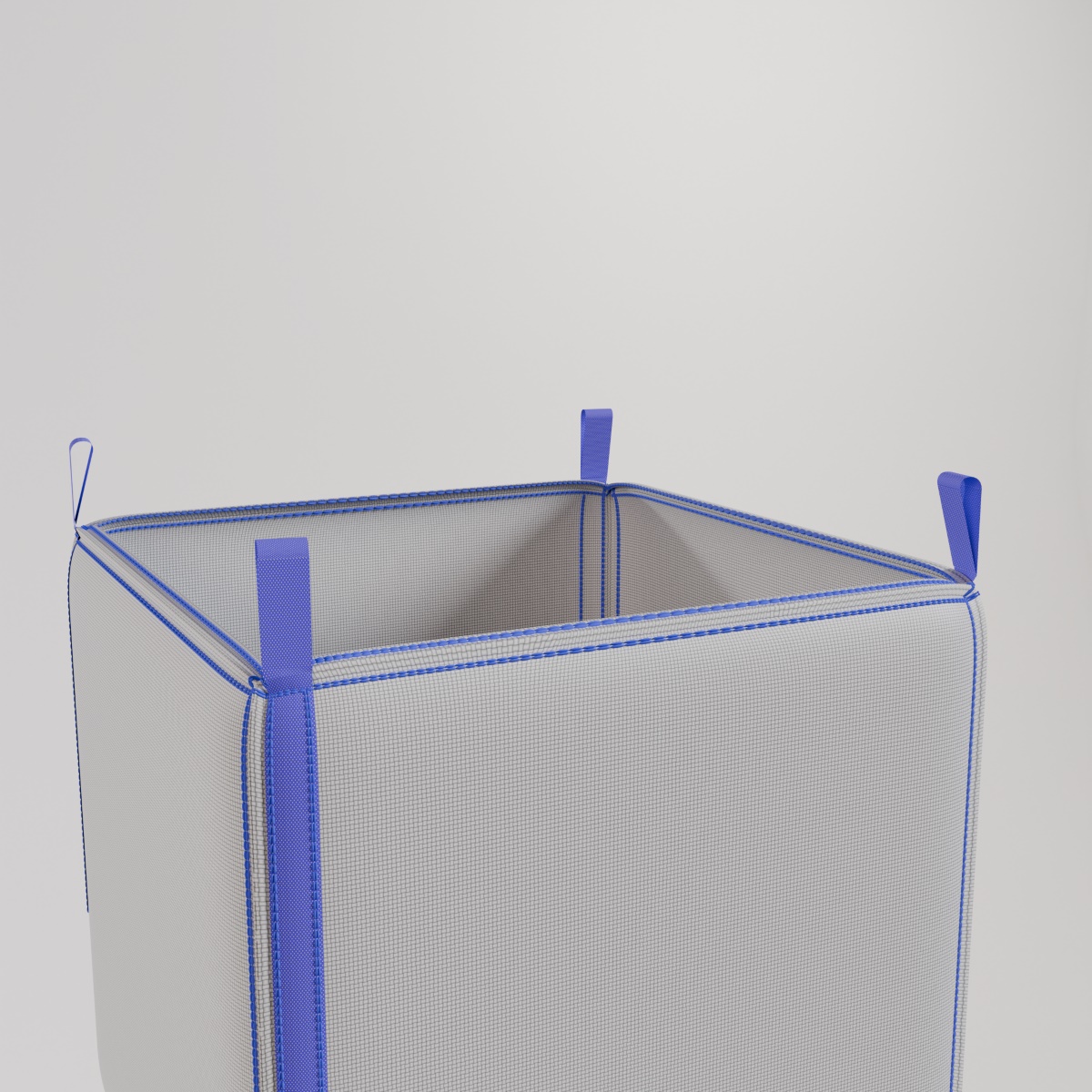

For storing dry granular materials, 4 Panel FIBC provides additional support to the product with its four stitched panels and box-like shape. With high durability of lifting loops, these bags are highly preferred for easy transportation using cranes.

Application:

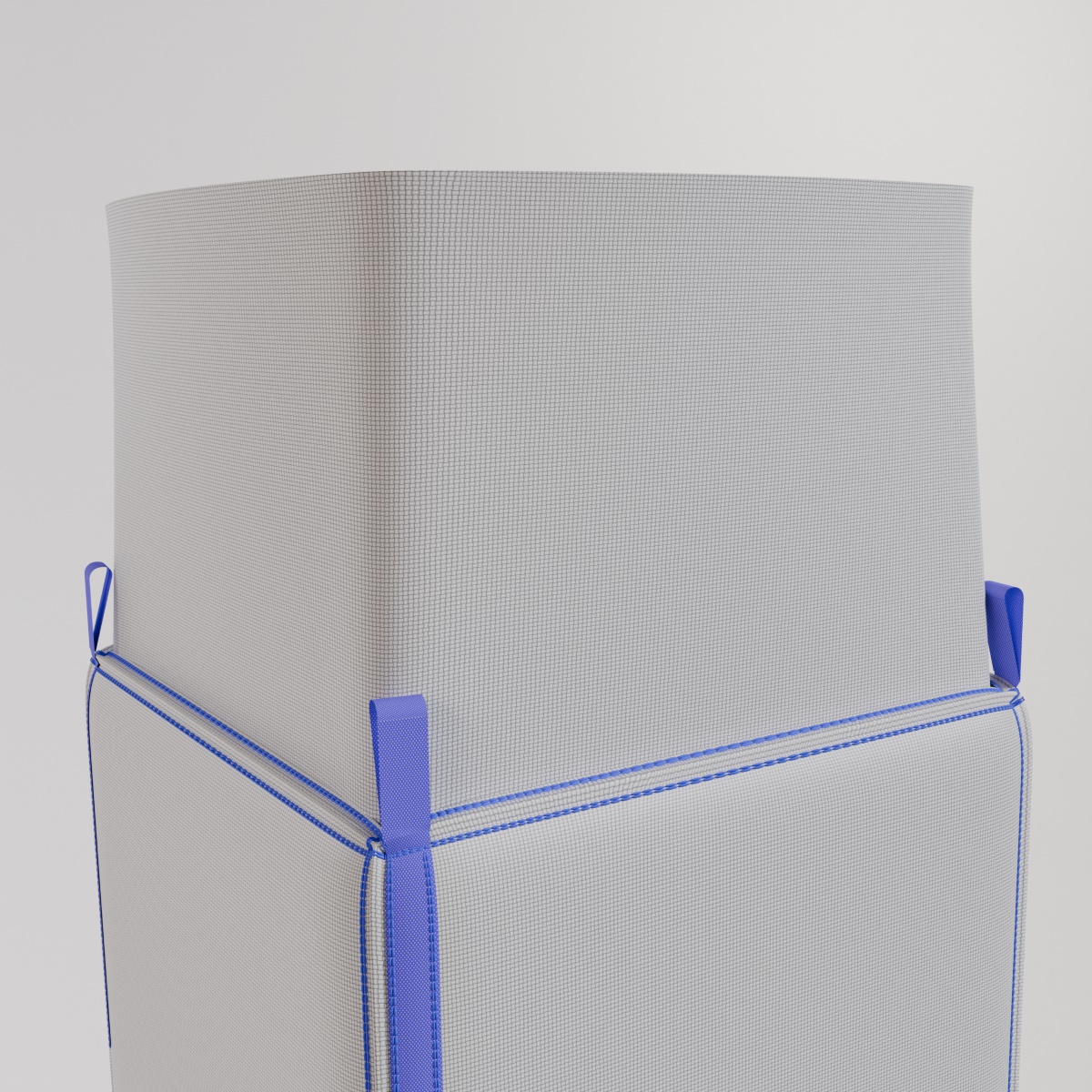

The Baffle Bags or Q-Bags as the name suggests have internal baffles that make stable during transportation and handling, preventing from bulging. They have various additional features that prevents the products from dust, spilling and wastage.

Application

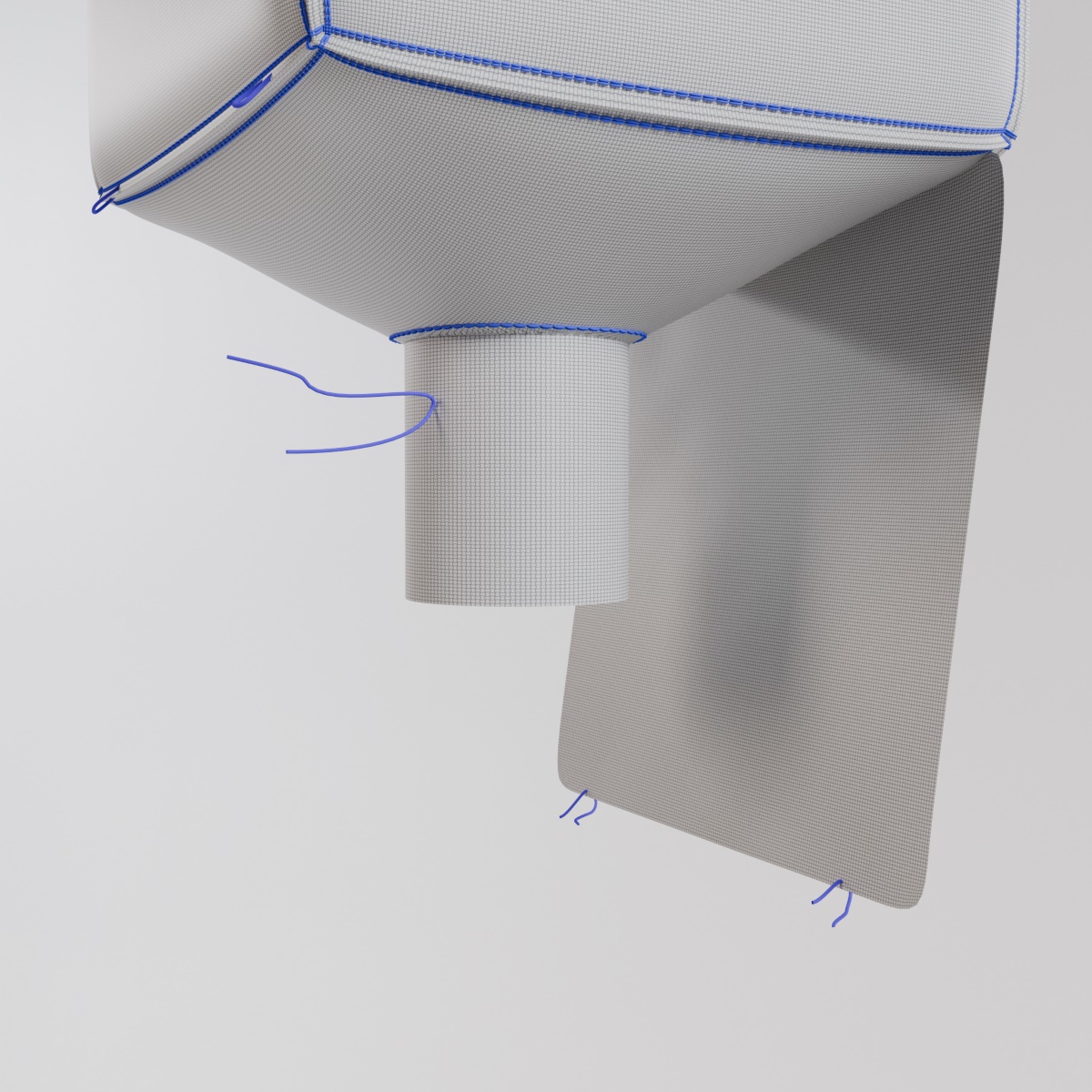

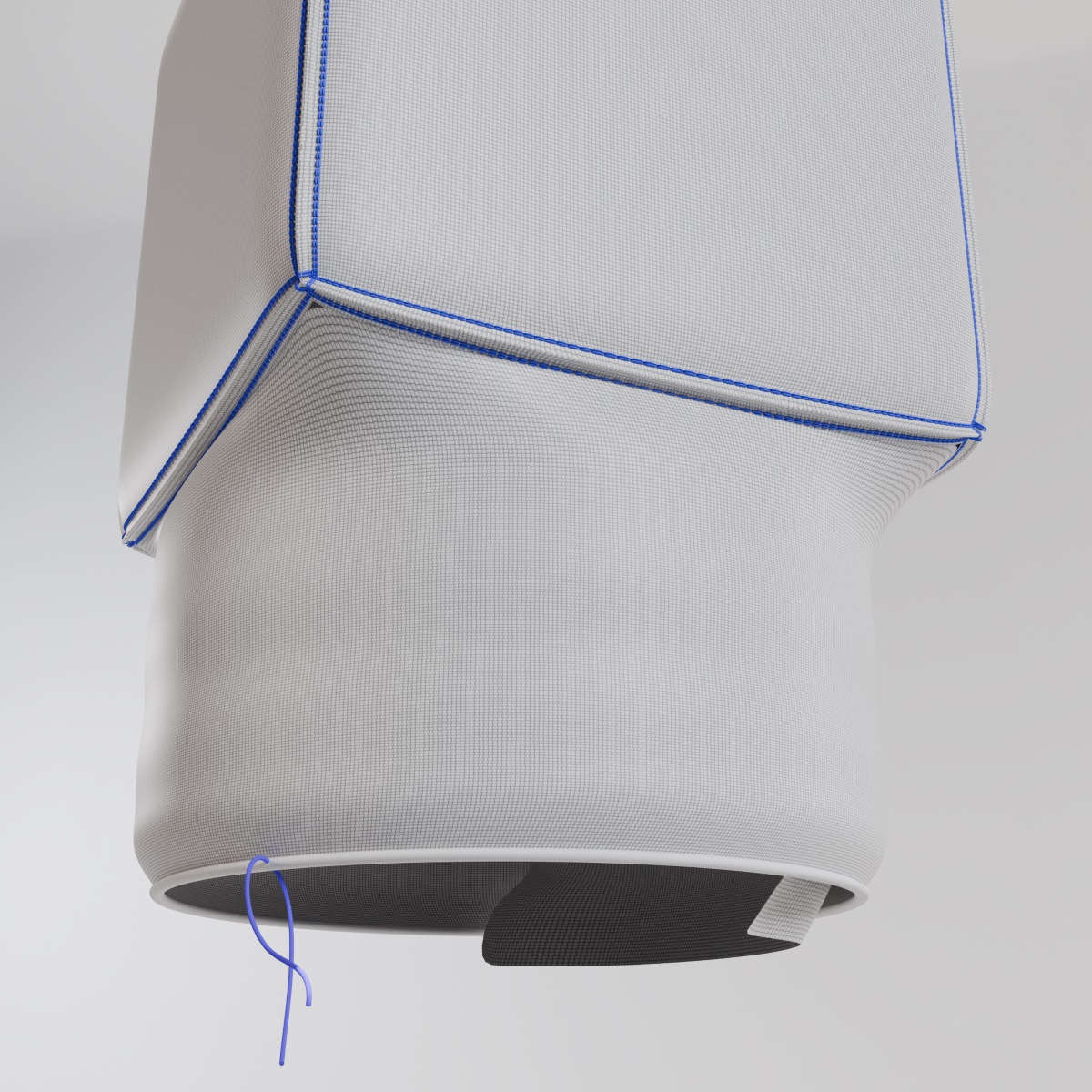

Circular Cross Corner FIBC bags are preferred across the Industrial Packaging due to their Flexible circular design that allows adjustability of bulk products or any other rough/undefined shaped products. The sewn cross-corner loops with only top and bottom panel folded eases their handling.

Application:

The D Loop FIBC Bags are mostly used in packaging for products that are prone to environmental exposure and protects the products with unique design and fabric including its single point lifting, ensuring easy handling.

Application:

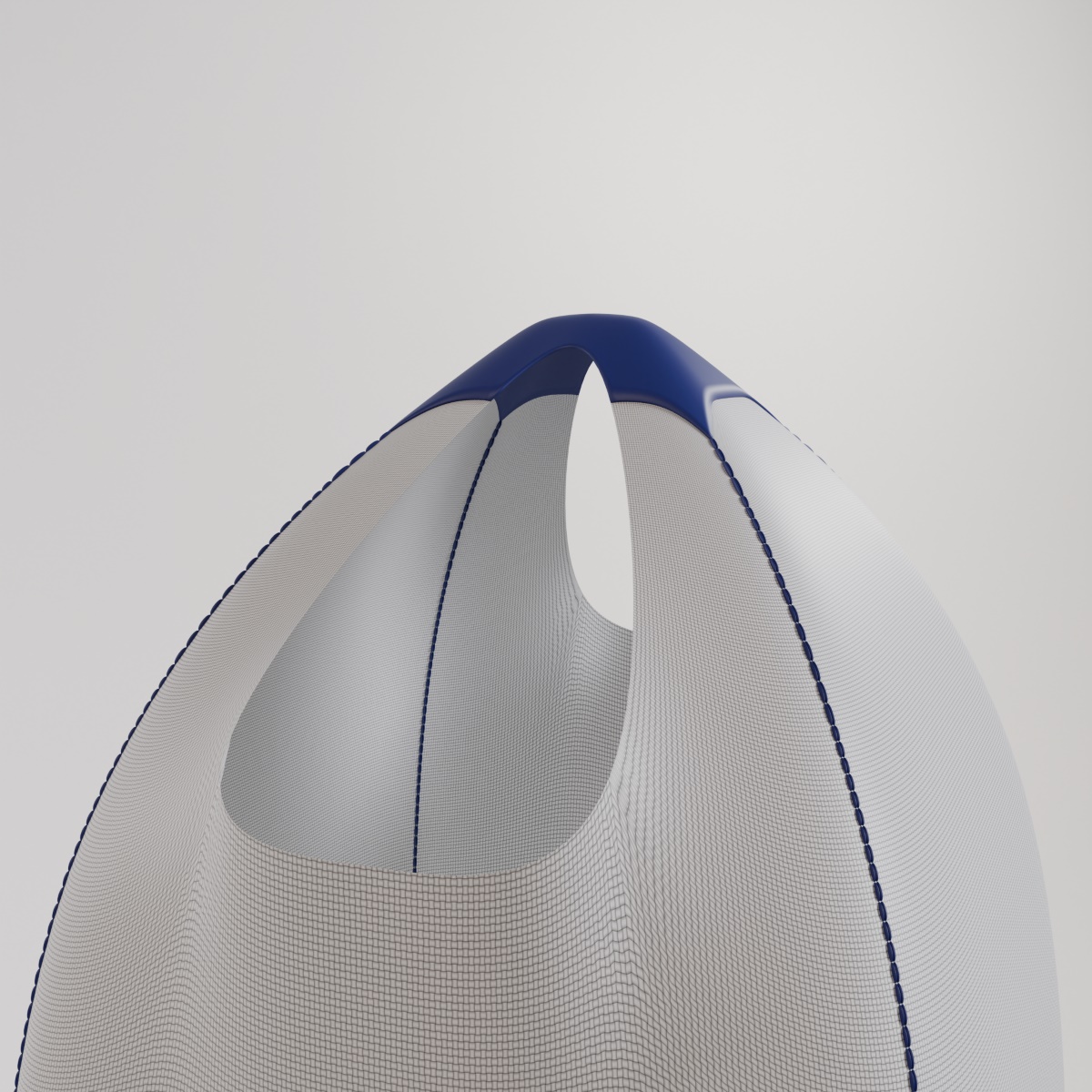

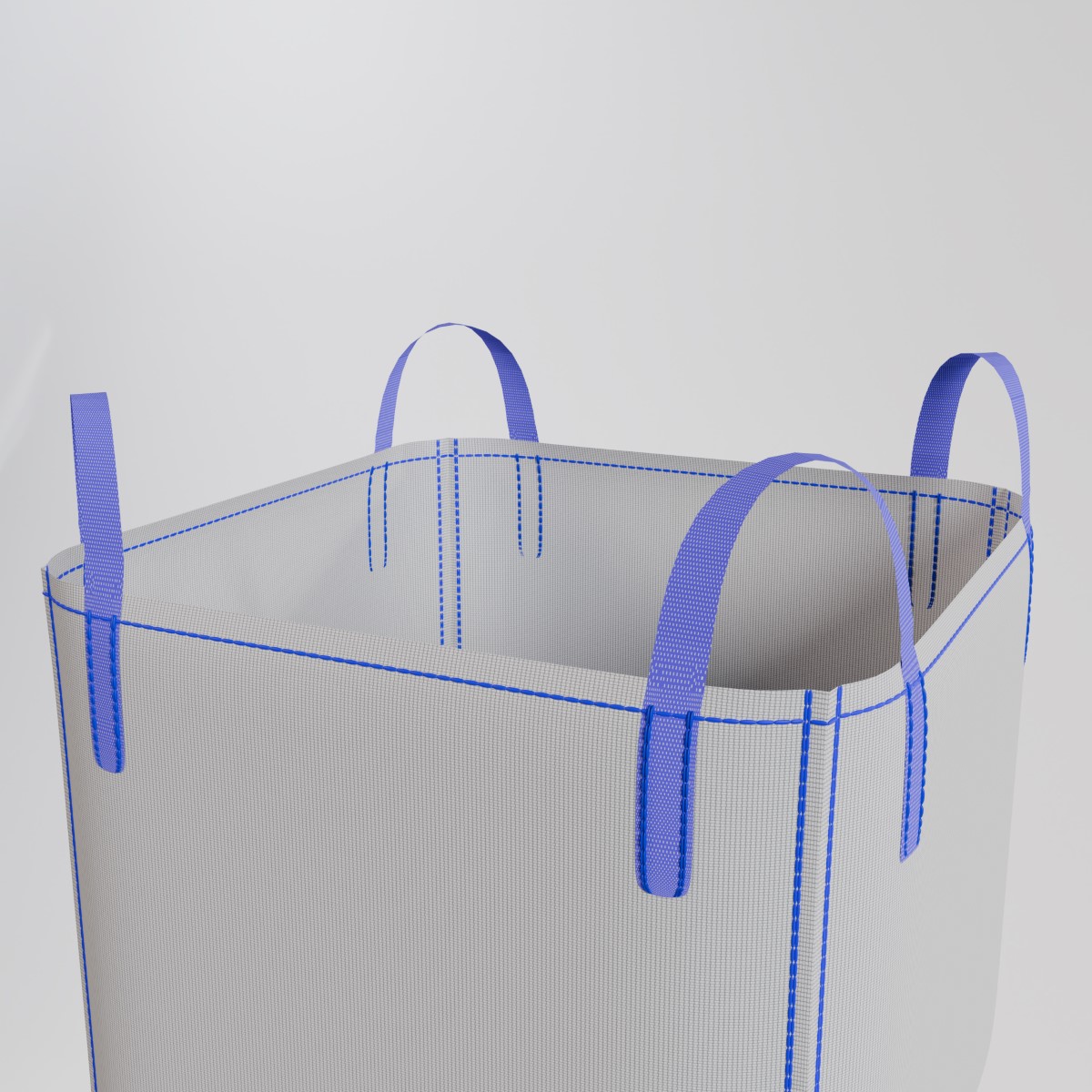

Full Loop FIBC Bags feature a single, continuous lifting loop integrated into the bag’s structure that makes it easier to be handled for transportation. Along with an affordable packaging solution, they are highly durable with bulk handling capacity.

Application:

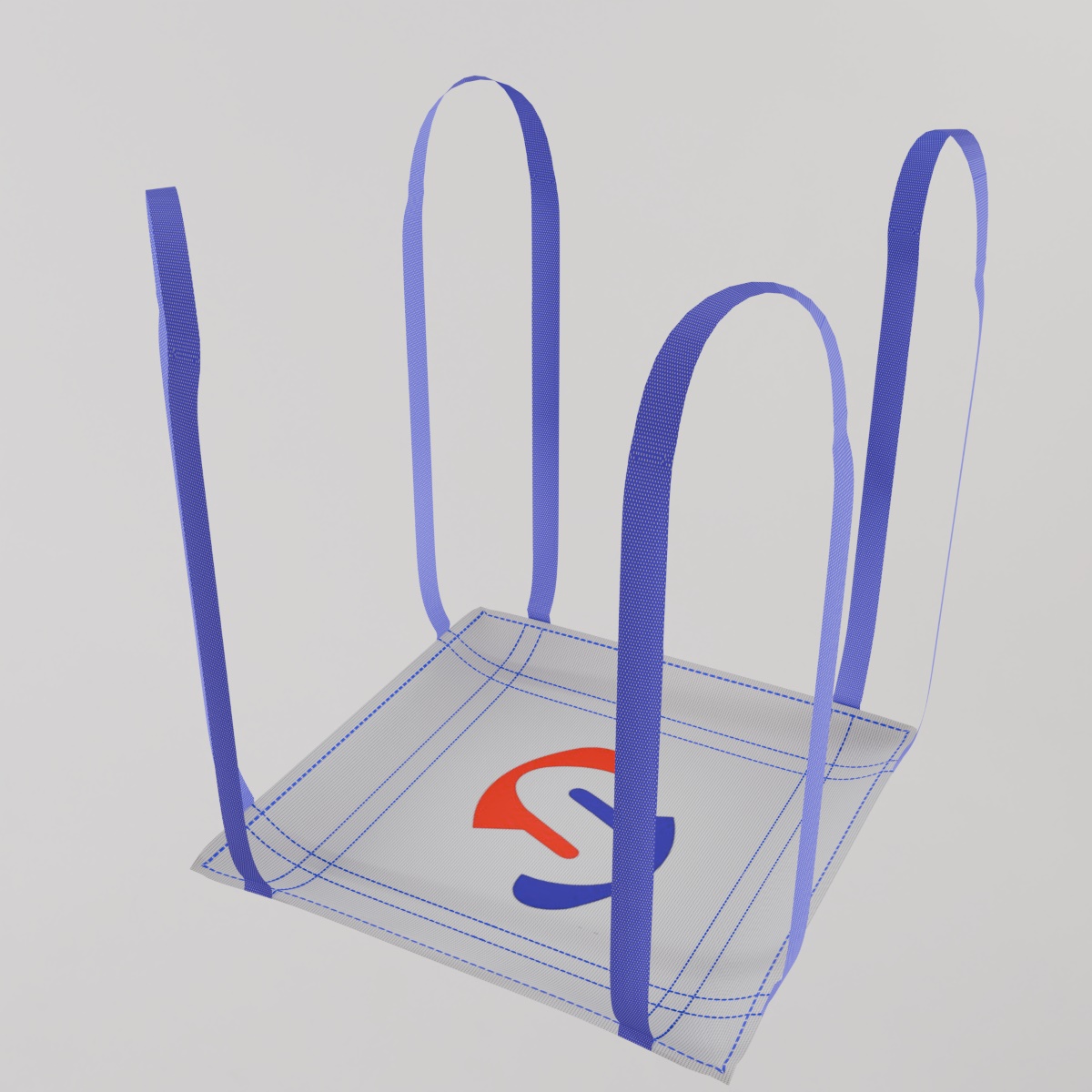

Platen/Palette FIBC Bags are made from woven polypropylene making them a preferred choice for durable, and flexible packaging options. Palette FIBC Bags are widely used for packaging of dry goods.

Application:

The Sling Jumbo FIBC Bags are an ideal choice for packaging of products that are loaded in heavy range due to their round and square shape preventing leaks, and reusability. With multiple lifting options, they are easy to handle and transport.

Application:

Tunnel FIBC Bags are widely known for their ease in transporting and handling the bulk materials minimizing the labor costs and also preventing the risk of accidents. They are made from high-quality polypropylene material ensuring their strength.

Applications:

The Side, Bottom, and Opposite Side structure of U Shape of U Panel FIBC Bags are stackable and durable in nature due to their structural strength. For products requiring efficient load distribution, these bags optimize space utilization and prevent the risk of collapse.

Applications:

Container FIBC Bags specialize in efficient storage and transportation of bulk materials. The container-like structure of these bags allows space-efficient filling and their strength prevents spoilage and contamination of products stored.

Applications:

The UN FIBC Bags are specially designed for storing and handling of materials that require additional safety and measures of protocols for handling and transportation. For products prone to international safety standards, these bags offer a reliable solution with testing principles.

Applications:

Ventilated FIBC Bags allows ventilation that is air flow through the products to prevent them from spoilage and ease the supply chain time and storage. These bags are commonly used for products to ensure freshness through special ventilated strips controlling moisture.

Applications:

1 Loop

2 Loop

D loop

Full Loop

2 Panel

4 Panel

Sling

Cross Corner

Skirt

Open

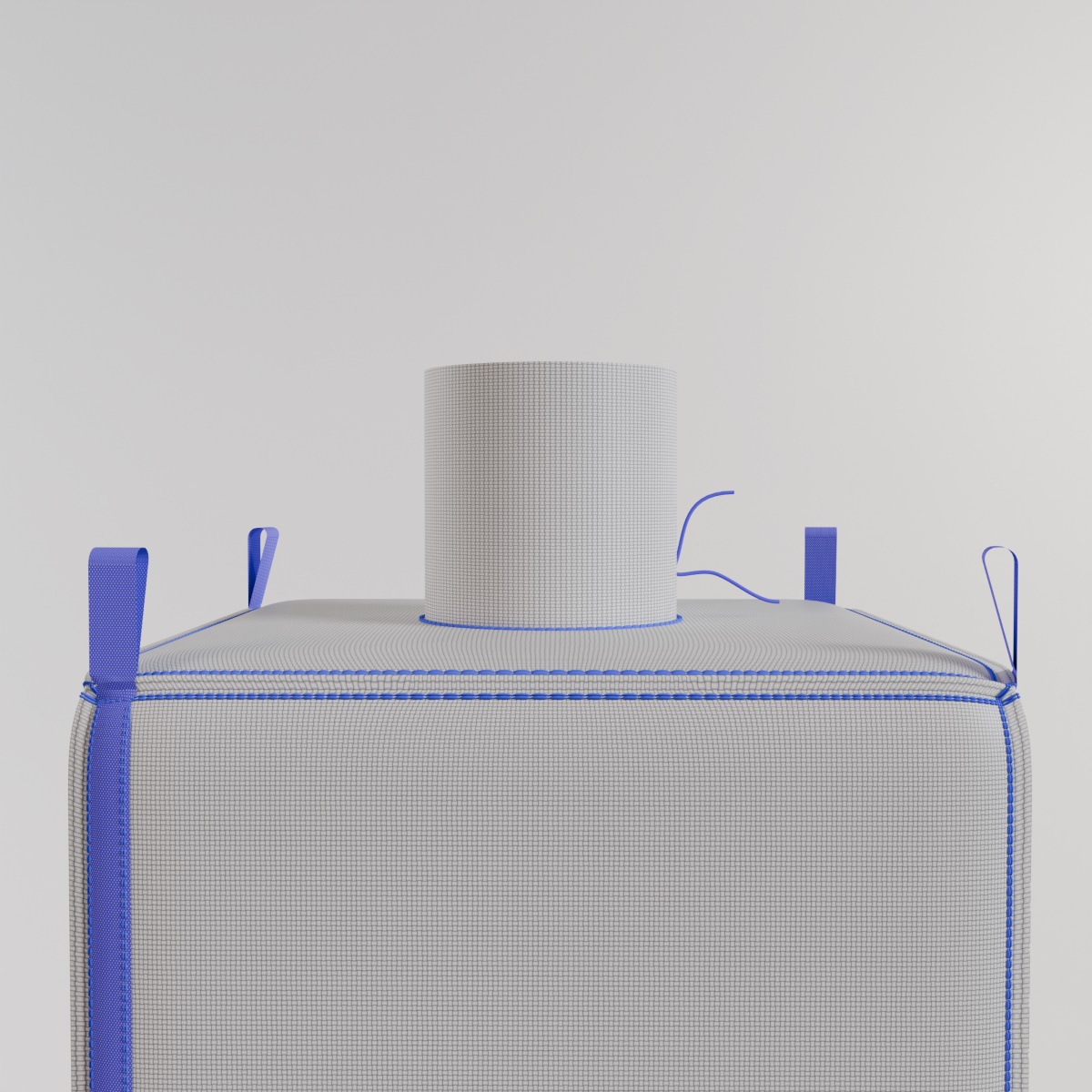

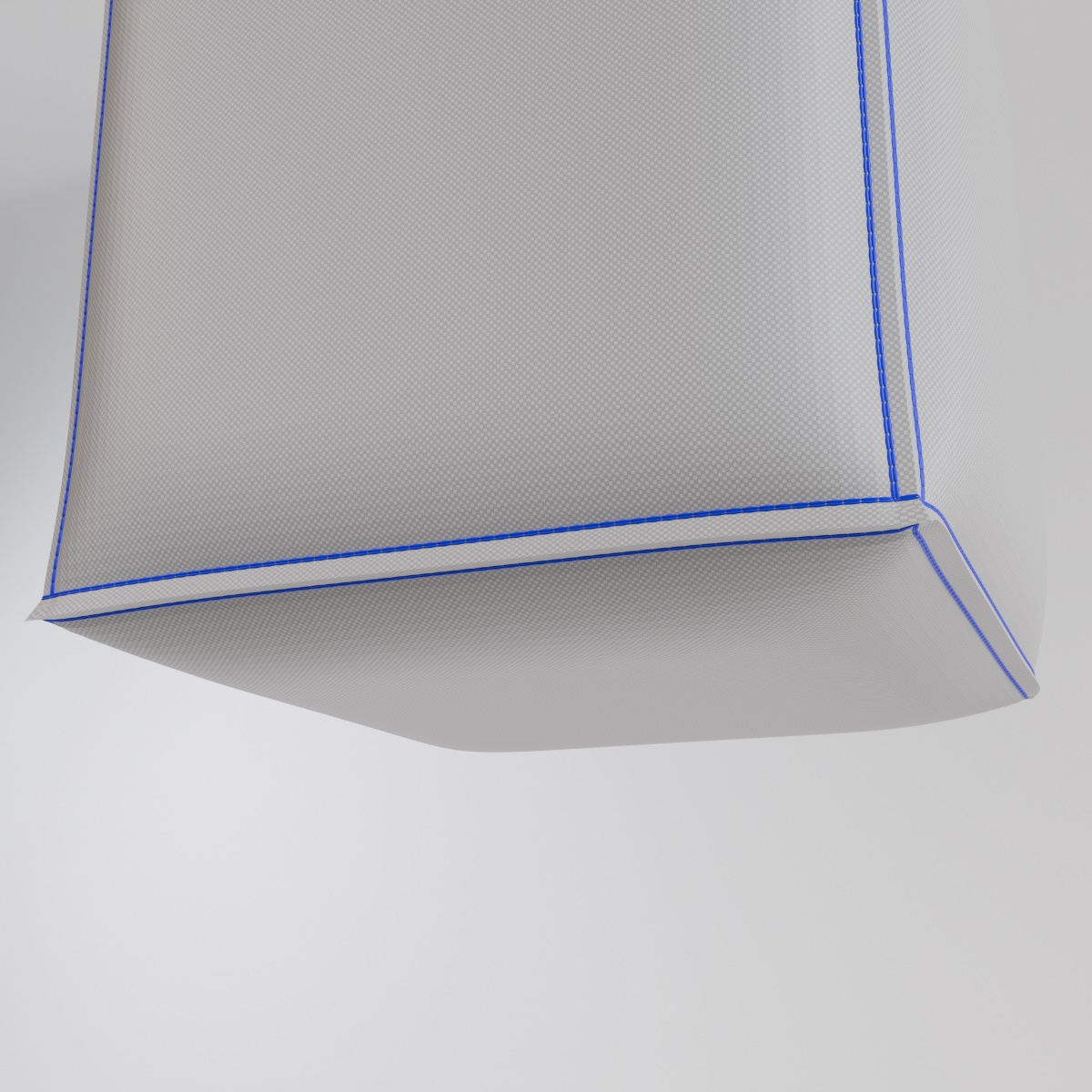

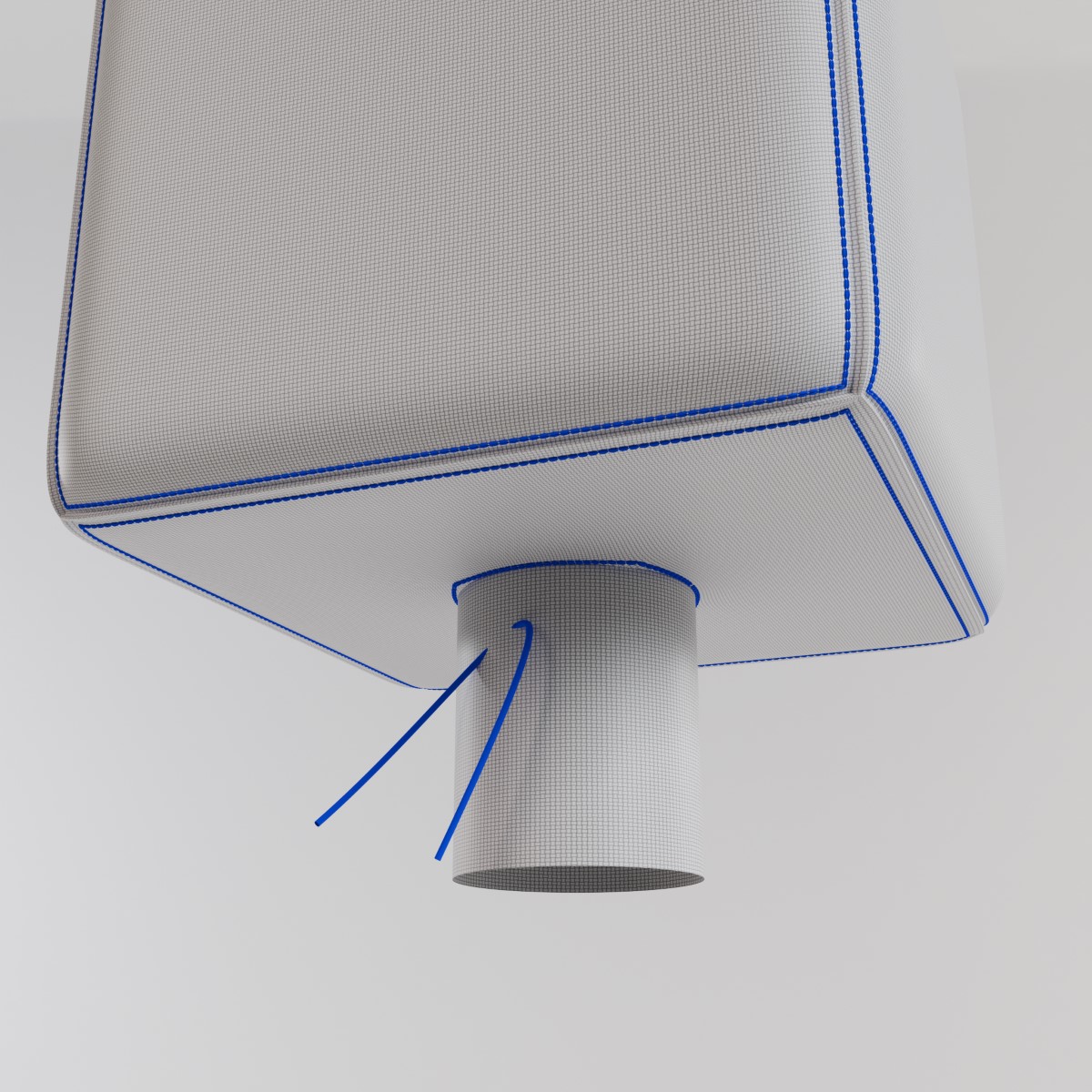

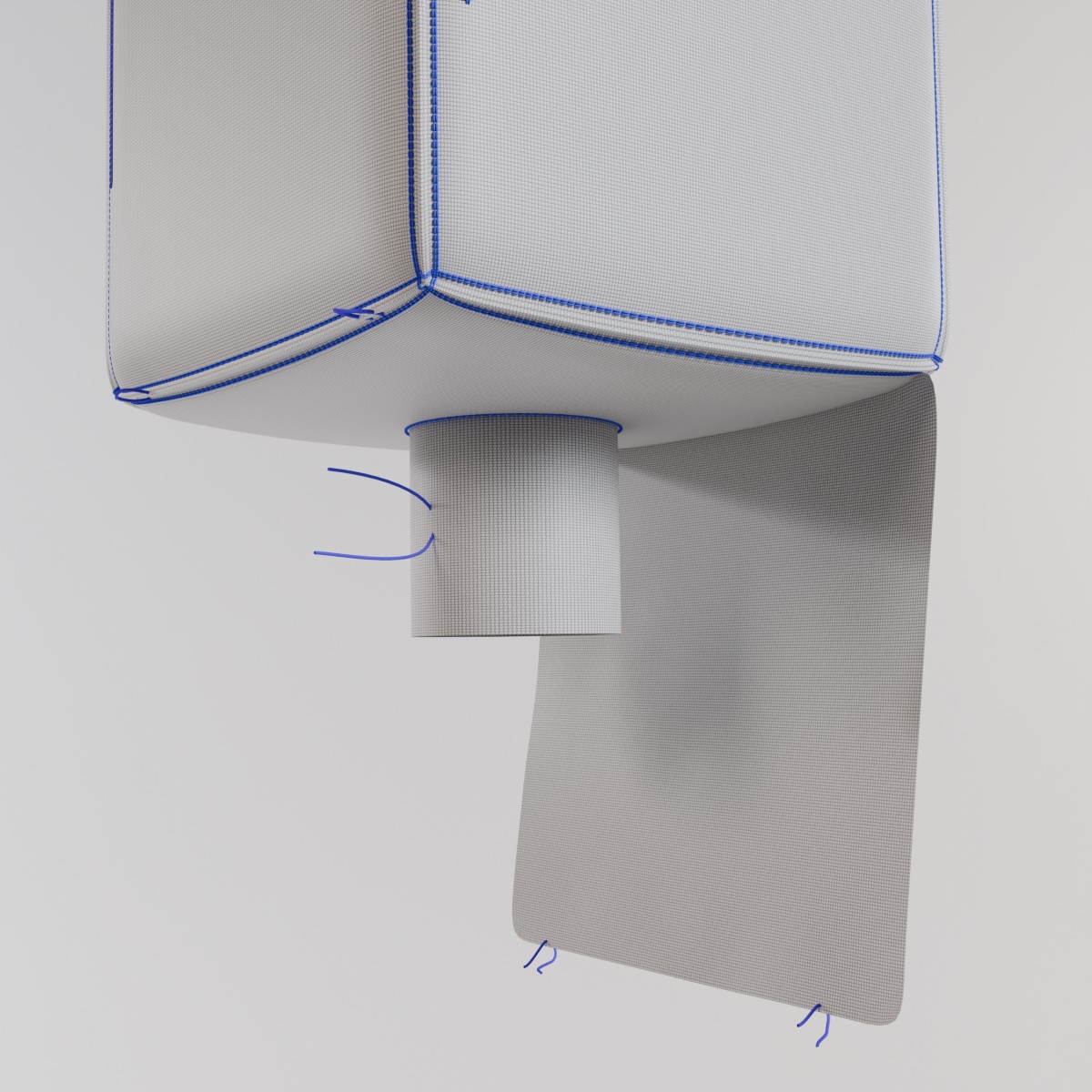

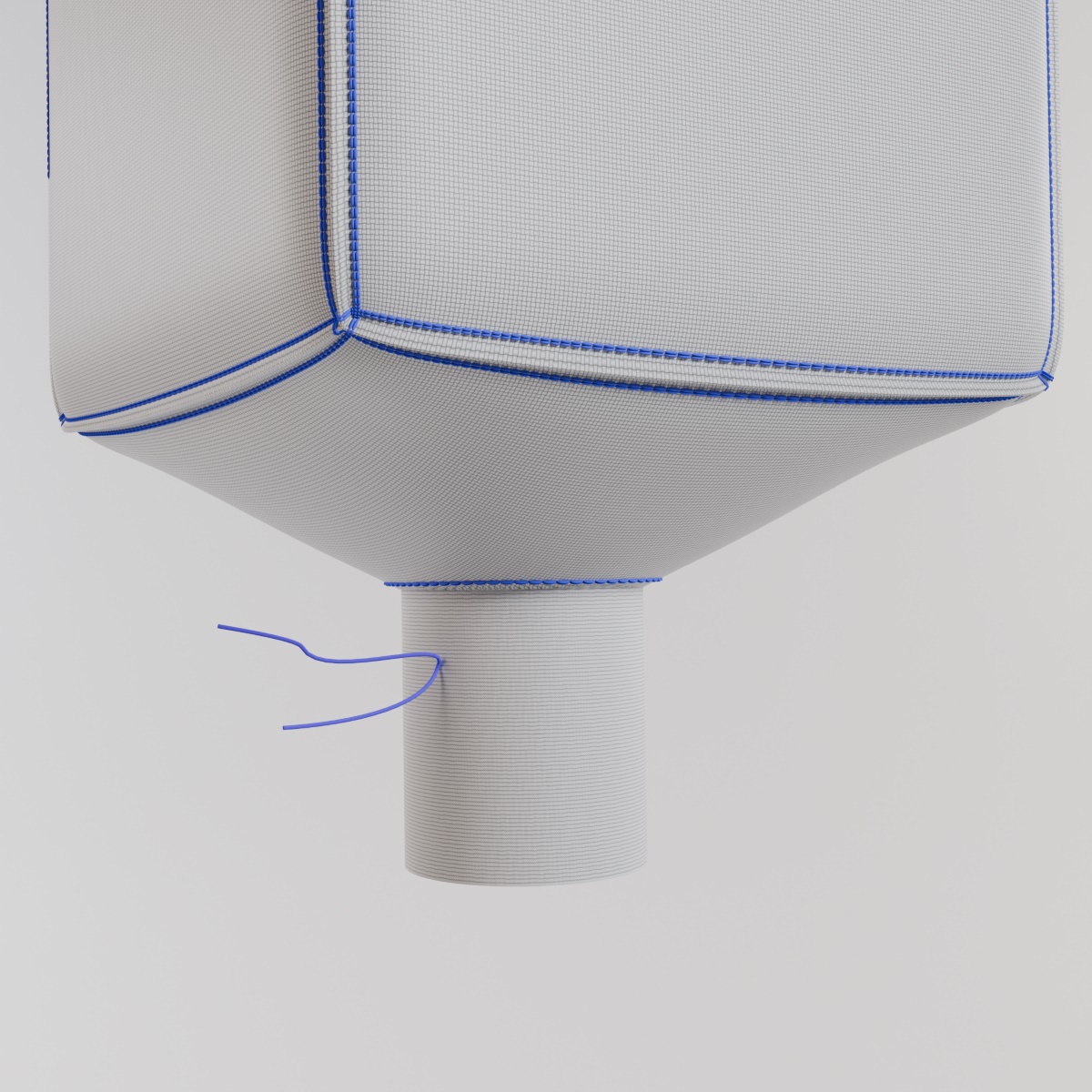

Flap

Spout

Flat Bottom

Spout

Spout with Flap

Conical Spout

Conical Spout with Flap

Open Spout Bottom with Flat

A significant achievement for Slogans FIBC Pvt. Ltd.! We’re proud to announce our official FIBCA certification and membership.

This recognition highlights our commitment to excellence in the FIBC sector. As a subsidiary of Slogan Group, our FIBC products are trusted globally, reaching over 32 countries with a production capacity of 25,000 jumbo bags/day.

This FIBCA milestone reinforces our dedication to providing superior bulk packaging solutions.

We’re excited to engage with the FIBCA community along with providing bulk bag solutions for enhancing the supply chain process and making it more efficient.